Description

Flavin Naturals Cellulase Enzyme Powder – Efficient Fiber Breakdown for Food, Beverage, and Nutraceutical Applications

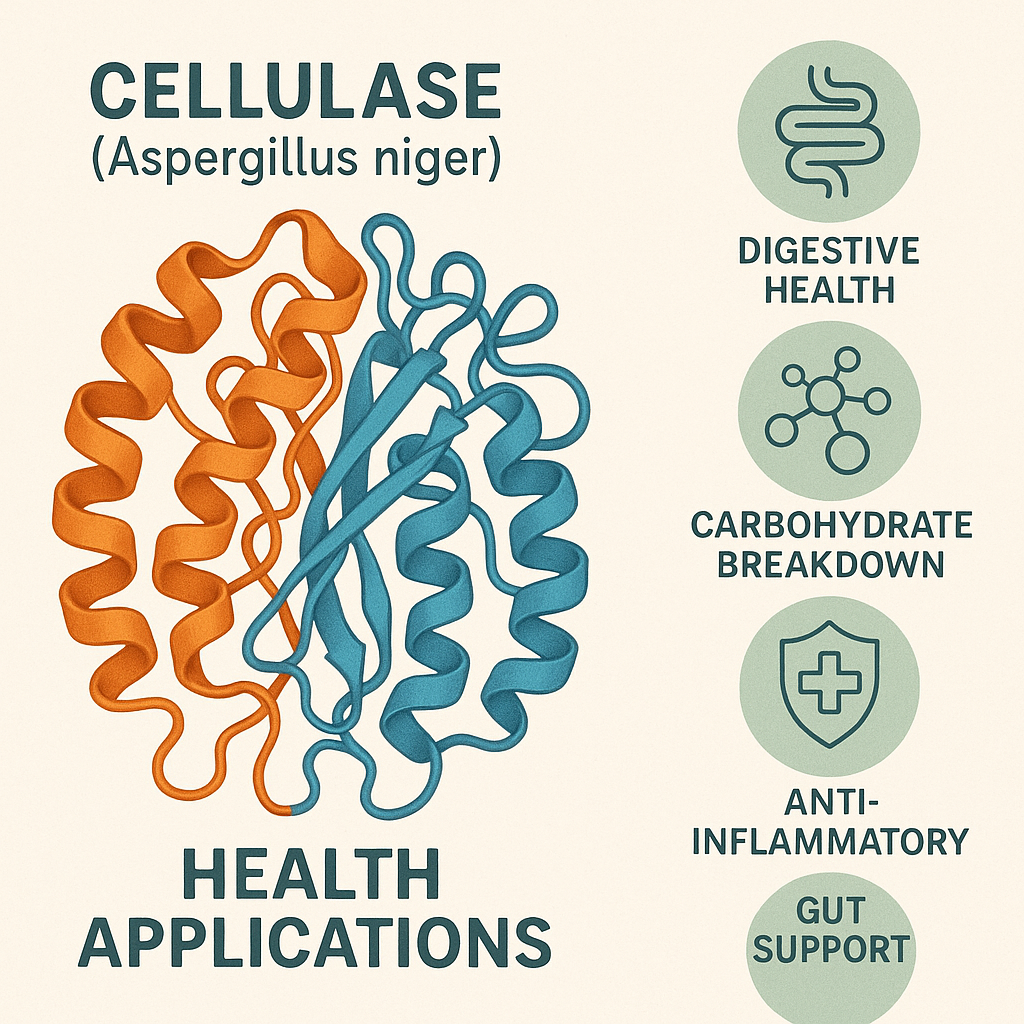

At Flavin Naturals, we provide high-activity enzymatic solutions crafted for the food processing, nutraceutical, and industrial enzyme markets. Our Cellulase Enzyme Powder (20,000 CU/g) is produced via fermentation of Aspergillus niger, delivering potent and consistent cellulolytic activity. Designed to hydrolyze cellulose into glucose and oligosaccharides, this enzyme supports enhanced fiber digestion, juice extraction, and improved nutrient bioavailability in functional formulations.

Key Advantages:

High Enzymatic Activity (20,000 CU/g):

Optimized for efficient cellulose breakdown, facilitating the conversion of complex plant fibers into simpler, digestible sugars.

Enhances Nutrient Bioavailability: Breaks down dietary fibers to release trapped phytonutrients, improving the nutritional profile of plant-based formulations.

Natural & Safe Microbial Source: Produced via controlled fermentation of Aspergillus niger, free from harmful additives, GMOs, or solvents.

Versatile Applications: Ideal for use in dietary supplements (digestive enzymes), fruit juice processing, brewing, and functional food enhancement.

Consistent Quality: Manufactured under GMP-certified processes with stringent activity standardization to ensure reliable batch-to-batch performance.

Features & Benefits of Cellulase Enzyme Powder

Source & Activity Specification:

Fermented from Aspergillus niger, standardized to 20,000 CU/g (Cellulase Units per gram) for precise fiber hydrolysis applications.

Appearance:

Fine, off-white to light beige powder, water-soluble for easy integration into powders, tablets, capsules, and liquid enzyme blends.

Functional Benefits:

-

Hydrolyzes cellulose and plant fibers into glucose and oligosaccharides.

-

Improves digestibility of high-fiber foods and supplements.

-

Enhances juice yield and clarity in fruit & vegetable processing.

-

Supports gut health and digestion when used in digestive enzyme formulations.

Optimal pH & Temperature:

-

Optimal pH Range: 4.5 – 5.5 (acidic to mildly neutral conditions).

-

Optimal Temperature: 45 – 55°C, stable across typical processing environments.

Recommended Applications:

-

Digestive enzyme supplements targeting fiber breakdown.

-

Fruit and vegetable juice extraction processes.

-

Brewing industry for mash efficiency and filtration enhancement.

-

Functional foods requiring fiber conversion for improved texture and digestibility.

Reviews

There are no reviews yet.